Off-road Struts Built on Decades of Design

ORI Struts are American-made, technologically advanced and built with a passion for performance. Years of development and design go into each state-of-the-art strut.

The story of our unique design begins where so many great journeys start: out on the trail. Mark and Marie Jensen used their passion for design and off-road racing and Mark’s more than 40 years of machining, engineering, and ISO 9000 global standard quality control experience to fabricate their first suspension systems, incorporating ORI Struts in 2002.

Mark gained an appreciation for precision engineering as a mechanic working on Honda motorcycles, and later as a machinist before completing formal studies in manufacturing engineering.

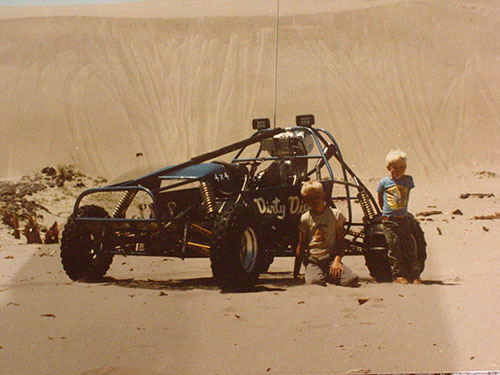

He put his training to use building award-winning 4×4 sand rails, including an 830-pound model with full independent suspension and enough horsepower to hurl a driver to speeds in excess of 100 miles per hour. The problem was — especially at those speeds and on steep side-hills — the need for improved stability.

His now-patented solution: the ORI Strut, with an innovative design that features dual pressurized chambers and internal bypass design to provide a level of stability not previously available on an off-road vehicle.

Today, ORI Struts represents everything that makes for the ultimate in off-road adventure: an American-made and quality-controlled product that delivers exceptional performance and unrivaled reliability from a family-owned business. Our lean manufacturing process and just-in-time production are behind the affordability of each internal bypass nitrogen strut.

Trust our world-wide network of dealers to connect you to the world’s most advanced suspension. That’s stability you can bank on.

Mark Jensen’s custom-built 1984 sand rail featured independent suspension, four-wheel drive and enough power to reach speeds in excess of 100 miles per hour. The innovative sand rail served as the inspiration for today’s performance-focused ORI Struts.

Made with Pride in the U.S.A.

ORI Struts are made in a specialized machine shop in the town of Bowdon, Ga., located just west of Atlanta. The plant formerly supplied parts for a tire factory. When the factory burned and the tire company left town, the shop found new life in building one of the world’s most advanced off-road stability systems. The shop features an array of sophisticated equipment used to manufacture each part, including:

- CNC lathes

- CNC machining centers

- CNC horizontal band saw

- 4-axis laser engraving system

- Surface-grinding equipment

- Manual mills, lathes and saws

- Fabrication and welding systems

- QA testing & inspection

- 5-ton bridge cranes

- High-pressure leak testing to 1,500 psi

- Solvent wash and aqueous ultrasonic cleaning

- Complete product assembly, testing and packaging

ORI Struts is a family company, with Mark and Marie Jensen ensuring that each manufactured part is up to the rigid quality standards for which the company is known and our customers rely.